Introduction

Bridge managers are required to identify optimal intervention

actions to be carried out on bridges so that these structures will

continue to provide adequate levels of service to society. In the

determination of optimal intervention strategies, bridge managers

are often challenged by the variety of different materials that

may be used in the interventions, long service lives, and long

periods of time between interventions. Existing methodologies

[1-4] are sufficient for modeling traditional intervention actions,

such as replacement or “patching” of bridge elements, where the

intervention can be assumed to change the condition state (CS), but

not the deterioration rate. These methodologies are inadequate,

however, for evaluating certain intervention actions, which can also

influence the deterioration rate of the element.

Walbridge et al. [5] proposed a methodology to evaluate

intervention strategies for bridges based on a total life-cycle

cost analysis (LCCA), wherein the costs (or impacts) of the

various intervention strategies on all of the bridge stakeholders

are considered. The proposed methodology used the CS-based

Markovian approach to model deterioration, and the costs

(or impacts) both during and between the interventions were

considered. The methodology was successfully used to evaluate

different intervention strategies for a steel roadway bridge. Fernando

et al. [6] further extended Walbridge et al.’s [5] methodology

to determine the optimal intervention strategy for roadway

bridges using steady state probabilities to determine the optimal

intervention strategy. Both the Walbridge et al. [5] and Fernando et

al. [6] models were limited to interventions where the deterioration

matrix remains unchanged, which is a common assumption, made

in many existing Markovian-based bridge management systems [7-

9]. In addition, except for the Walbridge et al. [5] model (where the

CSs are linked to probabilities of structural failure), it seems that

most other CS-based methodologies use predefined CSs, which are

not linked to structural failure [7-10], and thus ignore the safety of

the structure in the determination of optimal intervention strategy.

Walbridge et al. [5] consider the structural failure of the structure

in the CS definition. However, in their analysis, the probability of

condition improvement (i.e. replacement of the elements when

failed resulting in condition being improved to as new condition)

due to structural failure of the elements is ignored.

New intervention possibilities, such as fibre-reinforced

polymer (FRP) composite material strengthening, are increasingly

being used to retrofit deteriorating reinforced concrete (RC)

structures. When a RC beam is strengthened with FRP, the critical

deterioration mode of the strengthened beam becomes FRP-toconcrete bond degradation [11-12], which will have a different

deterioration rate (more likely a slower deterioration rate) than

that of the original RC beam (e.g. due to FRP providing a barrier

preventing chloride ingress and reinforcement to reduce rate of

fatigue damage, therefore rate of bond degradation becoming

faster than the reduced reinforcement corrosion rate). Traditional

Markovian models, commonly used in existing bridge management

systems, are not capable of modeling changes in the deterioration

rate as the result of an intervention. Some efforts have been

made [13] to model changing deterioration rates by relaxing the

history-independent deterioration assumption commonly used

in traditional Markovian-based deterioration models. The most

advanced of those models, such as the one described by Robelin and

Madanat [13], require considerable computational effort (e.g. to run

Monte Carlo simulations) to determine the deterioration matrices.

This approach, while attractive when many intervention actions

can result in changes of deterioration rates, is computationally

demanding when evaluating more simple problems such as

interventions on reinforced concrete (RC) structures, where only

a few intervention types are being considered. In addition, in the

method proposed by Robeling and Madanat [13], structural safety

is not explicitly considered.

The current paper presents a methodology to evaluate

intervention strategies that result in deterioration rate changes.

This methodology employs a modified CS-based transition

probability matrix to model deterioration, allowing changes in the

deterioration rate to occur during the analysis period as a result of

the modeled intervention strategies. A methodology to determine

the optimal intervention strategy based on steady state Markovian

probabilities is also presented. Finally, the proposed methodology

is illustrated using a hypothetical RC bridge girder where one of the

considered intervention options is FRP strengthening.

Life-cycle cost (or impact) model

In this section, a new model is proposed by modifying traditional

Morkovian deterioration models to account for the changing

deterioration rates. This study is specifically motivated by the

emergence of new intervention options, such as FRP strengthening,

where once strengthened the critical deterioration mechanism

may be changed from that of the pre-strengthened element.

For example, a possible intervention for a RC beam is to be

strengthened using externally bonded FRP laminates. After such

an intervention, the critical deterioration mechanism (in terms

of the strength reduction) of the strengthened beam becomes the

interfacial damage of the FRP-concrete interface [11-12], which will

have a different deterioration rate (typically slower) than that of

the original RC beam.

The model developed in this study takes into consideration the

following possibilities:

- Certain interventions may improve the condition of the

element without changing the deterioration rate/mechanism

(e.g. paint restoration of a painted steel girder).

- Certain types of interventions may improve the condition

of the element and also change the deterioration rate/

mechanism (e.g. FRP strengthening of RC girders).

- Interventions possible in an intermediate state of

deterioration may not be possible if structural failure occurs

(e.g. a deteriorating RC beam may be strengthened using

FRP strengthening. However, if the beam has experienced

structural failure, replacement may be the only viable option).

Therefore, it is important to distinguish between the failure CS

(typically considered as the worst CS in current practice) and

structural failure. Structural failure of an element may occur at

any stage irrespective of the CS of the element.

- Interventions such as FRP strengthening are aimed

predominantly at existing structures. Advantages of FRP

strengthening over conventional strengthening methods, e.g.

low labor costs, minimal disturbance to the traffic etc., may

not have the same significance when used in new structural

elements. Therefore, if structural failure occurs in an element

(un-strengthened or strengthened), it may or may not be

replaced by a new strengthened element. More likely, it will be

replaced by a new un-strengthened element.

In the following sections, first a condition-based transition

probability matrix considering the structural failure of an element

is presented. Secondly, a method to model interventions that will

not change the original deterioration rate (explicitly accounting for

structural failure)based on steady state Markovian probabilities is

presented. Finally, a model is proposed to account for interventions

that will result in a change in the deterioration rate.

Condition based transition probability matrix for

deterioration modeling

Transition probabilities represent the probability for an element

that is in CS i at time period t to be in state j at the following time

period (i.e. t+1). A typical transition probability matrix of an

element with n CSs can be written as:

with:

Where index e denotes the element of concern, and n is

the number of CSs for element e. An appropriate (stochastic)

deterioration model can be used to estimate the transition

probabilities in absence of inspection data.

In such a transition matrix the worst (i.e. highest) CS is defined

as the CS where the element performance becomes inadequate.

However, the probability that the element may experience

structural failure within a time interval is not explicitly considered.

The probability of the element structural failure is dependent on

the current CS of the element. In the current study, a new CS, i.e.

CSn+1, is introduced to accommodate the structural failure of the

element. The structural failure considered in this study is the result

of the applied load exceeding the structural resistance, thus causing

a sudden change in the structure condition. Therefore it is assumed

that, if the structural failure didn’t occur, deterioration (e.g.

corrosion) would continue to follow the normal path as predicted

by the stochastic deterioration model. With this assumption, a new

transition probability matrix can be written, considering the annual

structural failure probability of the element, as:

Where

Where Fei is the structural failure probability of an element in

CS i.

Case 1: When the interventions result in elements with

properties that are similar to the original elements

In typical Markovian models, interventions are assumed to

improve the condition of the elements, but assumed not to change

the deterioration rate. Therefore, deterioration matrix remains the

same after the interventions. If the element undergoes structural

failure, and is replaced by an element similar to the original, then

again the deterioration rate can be assumed to remain unchanged.

The effectiveness matrix of the intervention carried out at

CSs 1, 2, …, n+1can be defined using the transition probabilities

representing the probability for an element that is in CS i at the time

of intervention to be in state j after the interventions set x as:

With the properties:

Where '

i denotes the CSs where interventions will be carried out.

Note that this is an n+1 by n matrix, as any intervention carried out on the element will improve the condition, thus the probability of

structural failure is assumed to be negligible immediately after the

intervention. Also, it is reasonable to assume that the interventions

on any of the CSs i’=1, 2, ...,n (i.e. non-structural failure CSs) will

be carried out only if the element does not experience structural

failure prior to the intervention. If the element experience structural

failure, it will be immediately replaced by a new element. Therefore

the resulting deterioration-intervention matrix for a single time

interval can be written as:

Where

The CS of the element in any given year can be obtained by

multiplying the CS of the element at the beginning of each year by

deterioration-intervention matrix, ( )

' Q x,i e , i.e.:

where

is the CS

distribution of the element at time t=0.

The expected total costs or impacts in any given year are the sum

of intervention costs (in both structural failure and non-structural

failure CSs) and costs incurred due to the normal operations of the

bridge. Therefore, the expected cost or value of impacts in any given

year can be written as:

where ( 1)

πej(t −1) is the probability of element being in CS j in

time t-1,

c e,Ia,xis the value of impact a in carrying out intervention

x in non-structural failure CS '

i on element e,

c e,fais the value of

impact a in an event of the failure of element e,

ce,D a,jis the value of

impact a when the element is in operation and in CS j, d T ,tis the

length of the time interval t in days, and

'

dt (x,i) is the number

of days per time interval t that the structure is out of service due to

interventions x, which can be calculated as:

Where

d e,Ixis the number of days when the element will be out

of service for interventions x carried out on non-structural failure

CSs '

i , and

de,f n+1 is the number of days when the element will be

out of service due to failure.

The optimal intervention strategy, i.e. intervention set x, and CSs

'

i where the interventions will be carried out can be written as:

Case 2: When the interventions use elements with

different properties from the original elements

When an intervention changes the deterioration rate, the

above described modeling approach is no longer applicable. If the

deterioration rate changes, a new deterioration matrix is needed to

model for the post-intervention element. If such an intervention of

the original element is carried out in CSi, we can assume that the

element CS will transit to a new deterioration matrix, which has the

transition probabilities corresponding to the new element (postintervention element) deterioration rate. In order to represent

this in a transition probability matrix, the deterioration of the new

element (denote by index 2) is modeled using k+1 CSs with CS k+1

representing the structural failure of the new element:

The effectiveness vector of the interventions carried out at

structural failure can be defined using the transition probabilities

for an element in structural failure CS f(i.e. f=n+1, or f=k+1) at the

time of interventions x, to be in state j after the intervention as:

With

Where Int x ∈ denotes the element to be chosen to replace

the failed element, i.e. if Int=1, element similar to original element

(element 1) will be used, and if Int=2, then an element similar to the

new element (element 2) will be used.

Similarly, it is assumed that an intervention carried out on

element 1for CSs i=1,…,n, will have the option to use elements either

similar to the original element (i.e. element 1) or those similar to

element 2. The effectiveness matrix of the interventions for element

1 can be defined using the transition probabilities representing the

probability for element 1 in CS i at the time of intervention to be in

CS j (of element 1 or 2) after the intervention set x as:

with

Similarly, the interventions on element 2 can be using the

elements similar to element 1, or those similar to element 2.

Therefore, the effectiveness matrix of the interventions for element

2 can be defined using the transition probabilities representing the

probability for element 2 in CS i at the time of intervention to be in

CS j (of element 1 or 2) after the intervention set x as:

with

Effectiveness matrices for elements 1 and 2, considering

interventions on non-structural failure CS will be carried

out only if the elements didn’t fail, can be combined as:

With:

With:

Finally, the resulting combined deterioration-intervention

matrix can be written as:

With:

The CS of the element in any given year for interventions set x

carried out on CSs '

i can be written as:

Where

is the CS distribution of the element at t = 0.

Similar to the previous section, the expected value of impacts in

any given year can be written as:

where

πej (t −1) is the probability of element being in CS j in

time t – 1,

c e,Ia,x is the value of impact a in carrying out intervention

x in non-structural failure CS '

i on element e,

ce,fa is the value of

impact a in an event of the failure of element e,

c e,Da,jis the value

of impact a when the element is in operation and in CS j, dT ,t

is the length of the time interval t in days, and (x,i)

'

dt is the

number of days per time interval t structure is out of service due to

interventions x, which can be calculated as:

where

de,I xis the number of days when the element will be out

of service for interventions x carried out on non-structural failure

CS '

i , and

de,f(n+1) and

de,fk+1 are the number of days when the element

will be out of service due to structural failure.

Similar to previous section, the optimal intervention strategy

can be found using Equation 12, by replacing E(Vt(x,i')) by

Equation 25.

A simplified method to determine the optimal

intervention strategy

The method described above can be used to determine the

optimal intervention strategy, by determining the intervention

strategy resulting in the minimum life-cycle impacts. However, as

the impacts are calculated each year, the calculation procedure may

become computationally demanding. An alternative to determine

the optimal intervention strategy is proposed in this section using

the steady state properties[14], as is now being done in many

existing bridge management systems (e.g. [9]). Under stationary

transition conditions, the steady state probability of being in each

CS i, π i , when interventions x are performed on CSs '

i can be calculated by solving the following set of equations:

Using the steady state probabilities, the optimal intervention

strategy can be calculated as:

Example

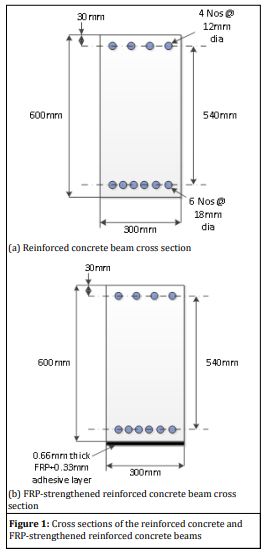

The purpose of this example is to demonstrate the use of the

proposed methodology to determine the optimal intervention

strategies for a hypothetical bridge element, when the interventions

could change the deterioration rate. FRP strengthening of reinforced

concrete (RC) bridge girders was assumed to be one of the available

intervention options. For illustrative purposes, representatives

RC beam cross sections with and without FRP strengthening are

provided in Figure 1.

With FRP strengthening, extended life spans can be expected

for bridge structures, thus the life-span of the bridge was taken as

150 years. Calculations were carried out using the methodology

presented in Section 2 for each year. The intervention strategy

resulting in the minimum total cost up to 150 years was taken as

the optimal intervention strategy. Also, the optimal intervention

strategy was determined based on the simplified method presented

in Section 3. Details of the example are given in the following

sections.

CS definitions

Typically, the CSs of RC elements subjected to reinforcement

corrosion are defined in terms of reinforcement section loss

[15].Similarly, in the current study the CSs for the RC beam were

defined based on the reinforcement section loss (Table 1). As the

main deterioration of the FRP strengthened RC beam is the bond degradation, the CSs for the FRP strengthened RC beam were

defined using the bond strength loss (Table 1). The CSs of the RC

beam are denoted by CCS, while the CSs of FRP strengthened RC

beam are denoted by FCS. The CSs of the FRP strengthened RC beam

were set so that, the worst CS (i.e. FCS3) gives equal performance

to the worst CS for the RC beam (i.e.CCS5). The structural failure

probabilities corresponding to each CS are also given in Table 1 for

both RC beam and FRP strengthened RC beam. As this example is

only to illustrate the methodology, details of the structural failure

probability calculations are not discussed

Deterioration matrices

The transition probabilities of the deterioration matrix for the

RC beam without considering the failure probabilities are given

in Table 2. Time interval is taken as one year. These transition

probabilities could be easily obtained using a stochastic corrosion

model [16-17]. As the corrosion initiation starts only in CCS2, there

is no change in annual structural failure probability from CCS1 to

CCS2. From CCS2 to CCS5, annual structural failure probabilities

increase due to strength loss as a result of reinforcement section

loss. In CCS5, RC girder will be considered as unsafe due to its

excessively high structural failure probability.

The transition probabilities of the adjusted deterioration

matrix (Equations 3 and 4) considering annual structural failure

probabilities are given in Table 3.

The transition probabilities of the deterioration matrix for the FRP

strengthened RC beam, without considering the structural failure

probabilities are given in Table 4. These transition probabilities

could be estimated using an appropriate bond-degradation model

coupled with a bond-strength model [18-19].

The transition probabilities of the adjusted deterioration

matrix (Equations3 and 4) considering annual structural failure

probabilities are given in Table 5.

Intervention options

The transition probabilities for different intervention activities

are shown in Table 6. In this table the rows correspond to the

bridge girder condition before the intervention is applied (at the

beginning of the time interval where the intervention will be carried

out), whereas the columns refer to the CS in the year following the

intervention. Four possible interventions: concrete cover repair

(possible in CCSs 2 and 3), concrete spalling and reinforcement

repair (possible in CCSs 2 to 5), replacement with a new concrete

beam (possible in CCSs 2 to 5, FCS3 and the structural failure CS,

i.e. CSF), and FRP strengthening (possible in CCSs 2 to 5) were

considered.

The identified intervention options are possible for bridge

girders either alone or in various combinations. The possible intervention combinations are normally determined by an expert

engineer. In many practical situations, the number of intervention

types and combinations will be limited to a finite set. For this

example a hypothetical list of possible intervention sets and the

CSs in which each intervention is permitted are given in Table 7.

In total, 5 different intervention sets with 20 possible intervention

strategies result from the list given in Table 7.

The costs corresponding to the CSs and intervention actions

are given in Table 8. They are divided into owner and public

costs. These costs are hypothetical. However efforts were made

to keep the ratios of their magnitudes reasonable. For the owner,

cover repair is very cheap ($15,000), compared to spalling and

reinforcement repair ($30,000), FRP strengthening ($35,000) or

replacement ($60,000). Spalling and reinforcement repair is still

cheaper than FRP strengthening, owing to the high material costs of

FRP (even though FRP strengthening will have lower construction

costs). For the public, costs during the interventions depend on

the intervention action. The public costs considered here include

costs due to noise during construction, increased travel costs due

to construction work, environmental costs, etc. When the bridge

is close, traffic has to be detoured and assumed to translate into

an additional public cost of $500 per day. If the bridge girder

experiences structural failure, a relatively high cost ($400,000) is

used to represent the possible injury and reconstruction costs.

The public costs due to normal operations of the bridge were

assumed to be dependent on the CS, and taken as $20,000,$2

4,000,$28,000,$35,000, and $80,000 for CCS 1-5 respectively

and $20,000,$24,000, and $60,000 for FCS1-3 respectively. The

relatively high public costs associated with CCS5 and FCS3 are due

to disturbances to the normal operations (e.g. restricted load limits,

etc.) owing to the reduced safety of the bridge. A simple Microsoft

Excel spreadsheet was setup to do the calculations.

Results

The calculation of the costs up to 150 years for all intervention

strategies was easily done using the spreadsheet. The calculation

effort for the simplified method was significantly less than that

for the year-by-year life cycle cost analysis up to 150 years. Both

methods are believed to be much easier than the existing methods,

which may require time-consuming MC simulations.

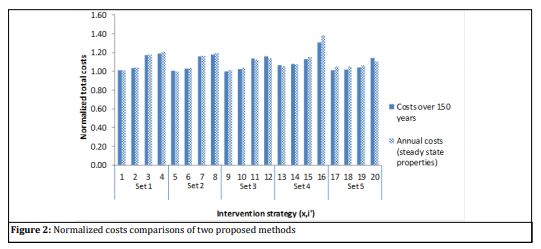

The calculated costs over 150 years and annual costs using stead

state properties are given in Table 9 for all of the intervention

strategies. In order to compare the results, normalized total costs,

i.e. normalized with respect to the minimum cost for each method,

are given in the last two columns. These normalized costs of each

strategy are also plotted in Figure 2. It is obvious that the results

from the simplified method generally are in a good agreement with

the calculated results over 150 years. The small differences were

found to occur due to differences in cost calculations in the years

before reaching the steady state. For some intervention strategies, it was also found that the steady state properties are not yet

achieved during the 150 years. The optimal strategy selected from

the cost minimization over 150 years was set 3, with interventions

for CCS2, CCS4, FCS3, and CSF, while the optimal strategy selected

using steady state properties was set 2 with interventions for

CCS2, CCS4, and CSF. However, the difference between the costs

obtained using steady state properties of these two intervention

strategies was only 0.2%. Considering generally good agreement of

two methods (Figure 2), the simplified method can be taken as a

good approximate method to determine the optimal intervention

strategy.

Table 1: CS description for reinforced concrete beams and FRP strengthened reinforced concrete beams

|

Condition state |

Description |

Failure probability |

concrete beam |

CCS1 |

as new, no corrosion |

0.0001 |

CCS2 |

corrosion initiation, <2% thickness loss |

0.0001 |

CCS3 |

moderate corrosion, <6% thickness loss |

0.0002 |

CCS4 |

high corrosion, <12% thickness loss |

0.0014 |

CCS5 |

severe corrosion, ≥12% thickness loss |

0.0054 |

FRP strengthened concrete beam |

FCS1 |

as new, loss in bond strength <10% |

0.0000 |

FCS2 |

loss in bond strength 10-25% |

0.0002 |

FCS3 |

loss in bond strength ≥25% |

0.0034 |

Table 2: Transition probability matrix for reinforced

concrete beam

Year (t) |

Year ( t+1) |

|

CS1 |

CS2 |

CS3 |

CS4 |

CS5 |

CS1 |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

CS2 |

0.0000 |

0.6200 |

0.3800 |

0.0000 |

0.0000 |

CS3 |

0.0000 |

0.0000 |

0.8410 |

0.1590 |

0.0000 |

CS4 |

0.0000 |

0.0000 |

0.0000 |

0.8940 |

0.1060 |

CS5 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

1.0000 |

Table 3: Adjusted transition probability matrix for reinforced concrete beams

Year (t) |

Year ( t+1) |

|

CS1 |

CS2 |

CS3 |

CS4 |

CS5 |

CSF |

CS1 |

0.9179 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0001 |

CS2 |

0.0000 |

0.6199 |

0.3800 |

0.0000 |

0.0000 |

0.0001 |

CS3 |

0.0000 |

0.0000 |

0.8408 |

0.1590 |

0.0000 |

0.0002 |

CS4 |

0.0000 |

0.0000 |

0.0000 |

0.8927 |

0.1059 |

0.0014 |

CS5 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.9946 |

0.0054 |

Table 4: Transition probability matrix for FRP strengthened beams

Year (t) |

Year ( t+1) |

|

FCS1 |

FCS2 |

FCS3 |

FCS1 |

0.9817 |

0.0183 |

0.0000 |

FCS2 |

0.0000 |

0.9878 |

0.0122 |

FCS3 |

0.0000 |

0.0000 |

1.0000 |

Table 5: Adjusted Transition probability matrix for FRP

strengthened beams

Year (t) |

Year ( t+1) |

|

|

FCS1 |

FCS2 |

FCS3 |

CSF |

FCS1 |

0.9817 |

0.0183 |

0.0000 |

0.0000 |

FCS2 |

0.0000 |

0.9877 |

0.0122 |

0.0001 |

FCS3 |

0.0000 |

0.0000 |

0.9992 |

0.0008 |

Table 6: Intervention options and their effectiveness

Intervention action |

After the intervention |

CS |

CCS1 |

CCS2 |

CCS3 |

CCS4 |

CCS5 |

FCS1 |

FCS2 |

FCS3 |

Cover repair |

CCS2 |

0.8500 |

0.0975 |

0.0525 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

CCS3 |

0.5507 |

0.2662 |

0.1330 |

0.0501 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

Spalling and reinforcement repair |

CCS2 |

0.9700 |

0.0300 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

CCS3 |

0.9600 |

0.0400 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

CCS4 |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

CCS5 |

0.8000 |

0.1500 |

0.0500 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

FRP strengthening |

CCS2 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.9817 |

0.0183 |

0.0000 |

CCS3 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.9817 |

0.0183 |

0.0000 |

CCS4 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.9817 |

0.0183 |

0.0000 |

CCS5 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.9817 |

0.0183 |

0.0000 |

replacement with a concrete beam |

CCS2 |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

CCS3 |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

CCS4 |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

CCS5 |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

FCS2 |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

FCS3 |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

CSF |

0.9180 |

0.0820 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

0.0000 |

Table 7: Possible intervention sets

Interventions set, x |

Intervention action |

Possible CSs, i' |

1 |

Cover repair |

CCS2, CCS3 |

Replacement |

CCS4,CCS5,CSF |

2 |

Cover repair |

CCS2, CCS3 |

Spalling and reinforcement repair |

CCS4,CCS5 |

Replacement |

CSF |

3 |

Cover repair |

CCS2,CCS3 |

FRP strengthening |

CCS4, CCS5 |

Replacement |

FCS3, CSF |

4 |

Spalling and reinforcement repair |

CCS2, CCS3, CCS4, CCS5 |

Replacement |

CSF |

5 |

FRP Strengthening |

CCS2, CCS3, CCS4, CCS5 |

Replacement |

CSF, FCS3 |

Table 8: Bridge closure days and intervention costs

Intervention action |

Applied CS |

Number of bridge closure days |

Costs (in thousands of dollars) |

Owner |

Public |

Total |

Cover repair |

CCS2 |

2 |

15 |

2 |

17 |

CCS3 |

2 |

15 |

3 |

18 |

Spalling and reinforcement repair |

CCS2 |

15 |

30 |

5 |

35 |

CCS3 |

15 |

30 |

5 |

35 |

CCS4 |

15 |

30 |

5 |

35 |

CCS5 |

15 |

30 |

5 |

35 |

FRP strengthening |

CCS2 |

2 |

35 |

2 |

37 |

CCS3 |

2 |

35 |

2 |

37 |

CCS4 |

2 |

35 |

2 |

37 |

CCS5 |

2 |

35 |

2 |

37 |

Replacement (with a concrete beam) |

CCS2 |

60 |

60 |

10 |

70 |

CCS3 |

60 |

60 |

10 |

70 |

CCS4 |

60 |

60 |

10 |

70 |

CCS5 |

60 |

60 |

10 |

70 |

FCS2 |

60 |

60 |

10 |

70 |

FCS3 |

60 |

60 |

10 |

70 |

CSF |

90 |

300 |

400 |

700 |

Table 9: The calculated costs up to 150 years and annual costs from steady state properties

Intervention set, x |

CSs of the interventions, i' |

Total costs |

Normalized total costs (Total cost/minimum total cost) |

Costs up to 150 years |

Annual costs (steady state properties) |

Costs up to 150 years |

Annual costs (steady state properties) |

1 |

CCS2,CCS4,CSF |

1086.54 |

22.57 |

1.012 |

1.011 |

CCS2,CCS5,CSF |

1108.10 |

23.27 |

1.032 |

1.042 |

CCS3,CCS4,CSF |

1256.04 |

26.33 |

1.169 |

1.179 |

CCS3,CCS5,CSF |

1275.83 |

26.95 |

1.188 |

1.207 |

2 |

CCS2,CCS4,CSF |

1076.49 |

22.32 |

1.002 |

1.000 |

CCS2,CCS5,CSF |

1101.79 |

23.10 |

1.026 |

1.035 |

CCS3,CCS4,CSF |

1244.19 |

26.06 |

1.158 |

1.167 |

CCS3,CCS5,CSF |

1267.50 |

26.72 |

1.180 |

1.197 |

3 |

CCS2,CCS4,FCS3,CSF |

1074.15 |

22.74 |

1.000 |

1.019 |

CCS2,CCS5,FCS3,CSF |

1095.89 |

23.19 |

1.020 |

1.039 |

CCS3,CCS4,FCS3,CSF |

1218.36 |

25.05 |

1.134 |

1.122 |

CCS3,CCS5,FCS3,CSF |

1243.06 |

25.48 |

1.157 |

1.142 |

4 |

CCS2, CSF |

1144.43 |

23.70 |

1.065 |

1.062 |

CCS3, CSF |

1154.03 |

24.06 |

1.074 |

1.078 |

CCS4, CSF |

1215.68 |

25.74 |

1.132 |

1.153 |

CCS5, CSF |

1406.87 |

30.96 |

1.310 |

1.387 |

5 |

CCS2,FCS3, CSF |

1083.25 |

23.51 |

1.008 |

1.053 |

CCS3,FCS3, CSF |

1089.34 |

23.55 |

1.014 |

1.055 |

CCS4,FCS3,CSF |

1119.97 |

23.78 |

1.043 |

1.065 |

CCS5,FCS3,CSF |

1225.74 |

24.77 |

1.141 |

1.110 |

Conclusions

This paper presents a methodology for evaluating the lifecycle impacts of intervention strategies for infrastructure such as

bridges, which considers the possible changing deterioration rates

due to interventions during the service life. The methodology was

developed based on the Markovian approach commonly used in

existing bridge management systems. The safety of the structure

was also considered by introducing an additional condition state.

Based on the steady state properties, a simplified method was

proposed to determine the optimal intervention strategies.

The proposed methodology is demonstrated for a hypothetical

concrete bridge girder, where one of the intervention options is

FRP strengthening. Several intervention options resulting in 20

intervention strategies were compared. The optimal strategy was

selected based on minimum total life-cycle cost up to 150 years as

well as based on minimum annual costs determined using steady

state probabilities.

The results showed that the proposed method can be effectively

used to evaluate intervention strategies that result in deterioration

rate changes, also in order to determine the optimal intervention

strategies. Results from the simplified model show a good

agreement with the results from the year-by-year life-cycle cost

analysis. However, some discrepancies occurred due to steady

state not yet being reached during the 150 year analysis period

and/or due to differences in costs in the early years (before the

steady state is reached). Nevertheless, the proposed methodology

is seen to provide an efficient means of considering the effects of

changing deterioration rates in evaluating the life-cycle impacts of

intervention strategies.

References

- Scherer WT, Glagola DM. Markovian models for bridge maintenance management. Journal of Transportation Engineering. 1994;120(1):37-51.

- Roelfstra G. Modeled' evolution de l'etat des ponts-routes enbeton. These n°2310 – Grade de Docteurès Sciences Techniques, Doctoral Dissertation, ÉcolePolytechniqueFédéral de Lausanne. Switzerland (in French), 2001.

- Orcesi A,Cremona C. Optimization of maintenance strategies for the management of the national bridge stock in France. Journal of Bridge Engineering, ASCE. 2011;16(1):44–52.

- Almeida J, Teixeira P,Delgado R. Life cycle cost optimisation in highway concrete bridges management. Structure and Infrastructure Engineering. 2013;1-14.

- Walbridge S, Fernando D, Adey BT. Cost-benefit analysis of alternative corrosion management strategies for a steel roadway bridge.Journal of Bridge Engineering,ASCE. 2013;18(4):318-327.

- Fernando D, Mirazei Z, Adey BT, Ellis RM. The application of benefit hierarchy to determine the optimal intervention strategies for bridges. Transportation Research Board 91st Annual Meeting. 2012:22-26, Washington D.C.

- Thompson PD, Small EP, Johnson M, Marshall AR. The Pontis bridge management system. Structural Engineering International, IABSE. 1998;8:303-308.

- Pontis. Version 4.0 Technical Manual Report. USA: FHWA, US Department of Transportation. USA, 2001.

- KUBA. KUBA-MS-Ticino-user's manual, release 3.0., F.D.o. Highways, Bern, Switzerland, 2005.

- Jiang Y, Sinha KC. Bridge service life prediction model using markov chain. Transportation Research Record. 1989;1223:24-30.

- Toutanji H, Gomez W. Durability characteristics of concrete beams externally bonded with FRP composite sheets. Cement and Concrete Composites. 1997;19:351-358.

- Karbhari VM, Chin JW, Hunston D, Benmokrane B, Juska T, Morgan R, Lesko JJ, Sorathia U, Reynaud D. Durability gap analysis for fiber-reinforced polymer composites in civil infrastructure. Journal of Composites for Construction, ASCE. 2003;7 (3):238-247.

- Robelin CA, Madanat S. History-dependent bridge deck maintenance and replacement optimization with Markov decision processes, Journal of Infrastructure Systems, ASCE. 2007;13(3):195-201.

- Ching WK, Huang X, Ng MK, Siu TK. Markov chains: models, algorithms and applications.International series in operations research & management science. Springer Science Business Media. 2013;189: New York, USA.

- Pontis. Pontis Bridge Inspection Manual. M.D.o. Transportation, Michigan, USA, 2007.

- Pedersen C, Thoft-Christensen P. Reliability analysis of prestressed concrete beams with corroded tendons.Instituttet for Bygningsteknik, Aalborg Universitetscenter, 1993.

- Vu KAT, Stewart MG. Structural reliability of concrete bridges including improved chloride-induced corrosion models. Structural Safety. 2000;22:313-333.

- Ouyang Z, Wan B. Modeling of moisture diffusion in FRP strengthened concrete specimens. Journal of Composites for Construction, ASCE. 2008;12(4):425-434.

- Tuakta C, Büyüköztürk O. Conceptual model for prediction of FRP-concrete bond strength under moisture cycles. Journal of Composites for Construction, ASCE. 2011;15(5):743-756.