Abstract

Superplasticizer is one of the most common types of chemical admixtures used in the mortar or concrete, especially that characterized high performance like Reactive powder concrete. Recently, the chemical admixture is considered as one of the main components of cement-based products due to it has a significant role to improve the physical and mechanical properties generally. Therefore, the experimental work of this research has been an attempt to study the influence of two types of superplasticizers with different dosages on the properties of reactive powder concrete. The workability, compressive strength, and saturated surface dry density of reactive powder concrete used two types of chemical admixture(superplasticizer) individual and in combination have been studied and compared together. The results indicated that the use of superplasticizer type ViscoCrete-5930 in individual or combination with superplasticizer type KUT PLAST PCE600 has a positive impact on the properties of reactive powder concrete especially its flowability and compressive strength.

Keywords:Reactive powder concrete; Superplasticizer; Flowability; Compressive strength; Saturated surface dry density;

Introduction

In general, Concrete is a building material made from cement, aggregates, and water and an additional material known as admixture that is added to modify and improve the properties of concrete. Reactive powder concrete is one type of concrete that characterized its high performance. This type of concrete needs a high amount of cement reached to more 1000 kg/m3. Due to the cement is the chemically active constituent, the high performance and high strength of such concrete depended on this material. The activity of cement is brought when mixing it with the water. Reactive powder concrete does not contain coarse aggregates. It has only fine aggregates. In general, the aggregate has no important role in the chemical reaction but its usefulness arises because it is an economical filler material with good resistance to volume changes which take place within the concrete after mixing, besides improving the durability of concrete [1]. Nowadays, more than 70% of in-situ concrete in the world is produced by using the ready mixed concrete industry. Such concrete producers are utilizing chemical admixture (Superplasticizer) which is readily available from various manufacturers. This admixture always utilized to improve the workability of concrete and to decrease the water amount added to concrete. Thus, it is improved its strength. This material is one type of water reducers, where it leads to the water amount used in the concrete mix significantly [2]. Many advantages are obtained when superplasticizer utilized in concrete; improve the workability of concrete with constant cement content; improve the placing of concrete and its compacting; decrease the water amount used in the concrete mix leading to increase its strength; and also design a normal strength and workability with less cement content[3]. Also, the use of superplasticizer overall has positive influences on the fresh properties and hardened properties of concrete [4]. The effect of superplasticizer on the properties of concrete is different with the different type of superplasticizer used in the preparation of concrete [5]. So, the main objective of this study is to investigate the influence of using two different types of superplasticizer (ViscoCrete-5930 and KUT PLAST PCE600) on the flowability, strength, and density of reactive powder concrete cured with normal tap water.

Experimental Study

Materials

Ordinary Portland Cement (OPC) was utilized in this study. It was according to Iraqi specification No. 5/1984 [6]. local river sand was used as fine aggregate in all mixes. It was prepared as per ASTM C778 [7]. The grading of sand and its physical properties and chemical composition were listed in Table 1-2. Two types of chemical admixtures (Superplasticizer) were used to improve the workability and strength of concrete. The first one was a Highperformance superplasticizer concrete admixture. The commercial name of this type was ViscoCrete-5930. It was provided by the Sika company for chemical admixtures, Erbil, Iraq. The other type of chemical admixture was a High-performance concrete superplasticizer based on modified polycarboxylic polyethers. The commercial name of this type was KUT PLAST PCE600. It was obtained from Specialties construction chemicals factory, Jahra, Kuwait. Normal tap water was utilized in all mixes. The typical characteristics of two types of superplasticizer mentioned above were listed in Table 3.

Table 1: Grading of Local river sand used in this study.

Sieve No. (mm) |

Cumulative passing, % |

BS: 882:1992 |

No.4 (4.75) |

100 |

100 |

No.8 (2.36) |

100 |

80-100 |

No.16 (1.18) |

100 |

70-100 |

No.30 (0.60) |

73.1 |

55-100 |

No.50 (0.30) |

11.5 |

5-70 |

No.100 (0.15) |

2.2 |

- |

Table 2: The physical properties and chemical composition of River sand used in this study.

Physical property |

Value |

Specific gravity, gm/cm3 |

2.577 |

Absorption, % |

2.66 |

Fineness modulus |

2.132 |

Amount of clay, Silt, and Dust, % |

2.8 |

Chemical composition |

Constituent, % |

Ferric oxide, Fe2O3 |

2.716 |

Calcium oxide, CaO |

9.029 |

Silicon dioxide, SiO2 |

75.49 |

Potassium oxide, SO3 |

0.044 |

Alkalies (K2O + Na2O) |

4.815 |

Manganese oxide, MnO |

0.042 |

Magnesium oxide, MgO |

1.019 |

Aluminum oxide, Al2O3 |

9.265 |

Table 3: The typical characteristics of two types of superplasticizer used in this study

Typical characteristics |

ViscoCrete-5930 |

KUT PLAST PCE600 |

Specific gravity |

1.11±0.01@20ºC |

1.06-1.08@20ºC |

Setting time |

- |

No retardation at normal dosage |

Air entrainment |

- |

˂1%additional air is entrained |

Chloride content |

It is not contain chloride |

Nil to Bs 5075 |

Calcium chloride content |

It is not contain calcium chloride |

Nil |

Mix proportions

In this study, four dosages of ViscoCrete-5930 superplasticizer and KUT PLAST PCE600 superplasticizer were used in the preparation of reactive powder concrete. Table 4 was shown the dosages of superplasticizer used in such concrete. The mix proportion of cement to sand was constant. It was 1:1 by mass. The water to cement ratio (W/C) was 0.32.

Samples preparation

As soon as the mixes of concrete were prepared, the workability of each mix was tested. The standard test method for measuring the flow of hydraulic cement mortar as per ASTM C1437 [8] was depended on to determine the workability (flowability) of concrete. Then, all the mixes were poured in cast-iron molds. A total of 45 iron cubes of size 50×50×50 mm was cast for measuring compressive strength at age 3, 7, and 28 days (5 mixtures × 3 ages × 3 samples). The same specimens of age 28 days were used to determine the saturated surface dry density. All the specimens were prepared at room temperature 25 ± 2ºC and after twenty-four hours of molding, the samples were removed from the molds and cured by normal tap water at 18±2˚C and tested at the ages mentioned above.

Test methods

Workability

The workability of each mix prepared in this paper was determined according to ASTM 1437 [8]. The mini-slump cone, mini tamping rode and flow table was used to conduct this test. The cone was filled with a mixture of concrete prepared by two-layer, the thickness of the first one has filled the half cone and the second layer was filled the cone. The mini tamping rode was utilized to compact the two layers mentioned above by twenty blows for each one. After that, the cone was removed slowly to allow the concrete mixture to flow evenly on the table. Then, the flow table was dropped 25 times and the average of three readings of concrete diameter was recorded, as shown in (Figure 1a). The following formula (F1) was used to calculate the fluidity(workability) of concrete prepared.

Table 4: The dosages of superplasticizer used in the reactive powder concrete.

Dosage of KUT.(%) ** |

Dosage of Visco.(%)* |

W/C |

Cement : Sand |

Mix Number |

- |

2 |

0.32 |

1:1 |

1 |

2 |

- |

0.32 |

1:1 |

2 |

1 |

1 |

0.32 |

1:1 |

3 |

0.5 |

1.5 |

0.32 |

1:1 |

4 |

1.5 |

0.5 |

0.32 |

1:1 |

5 |

Compressive Strength

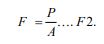

The compressive strength of each sample of size 50 mm3 was tested as per ASTM C109 [9]. The Digital compression-testing machine was utilized to measure the load applied to the samples, as shown in (Figure 1b), at curing age 7, 28, and 90 days. Three samples were used for evaluating the compressive strength of each mix prepared in this study where the average of the strength values was reported. The following Formula (F2) was used to calculate the compressive strength of each mix prepared.

Where F is the compressive strength, P is the maximum applied load on the sample, and A is the sample area exposed to the applied load.

Saturated Surface Dry Density

After 28 days of water curing, the concrete samples removed from the normal water and left in the air to dry its surface. Then, the weight of the samples was measured and recorded. The following formula (F3) was used to computed the saturated surface dry density. The average of three values of the density was considered.

Where Ds is the saturated surface dry density, W is the weight of the sample, V is the volume of the same sample.

Results and Discussions

Workability (Flowability or fluidity)

Table 5 lists the results obtained from the workability test of reactive powder concrete mixes prepared using different dosages of two types of superplasticizers. The results indicate that the flowability of the concrete mix containing superplasticizer type ViscoCrete-5930 is more than that of that containing superplasticizer type KUT PLAST PCE600. The presence of superplasticizer type ViscoCrete-5930 with dosage 2% by weight of cement leads to increase the flowability of the concrete mix in comparison with that of superplasticizer type KUT PLAST PCE600. Also, the use of two different dosages of two chemical admixtures (ViscoCrete-5930 and KUT PLAST PCE600) at the same time in the mix was investigated. As shown in the mentioned table, the use of dosage 1.5% of ViscoCrete-5930 by weight of cement with 0.5% of KUT PLAST PCE600 by weight of cement led to increase the workability of the concrete mix in comparison with mixes containing of 1% ViscoCrete-5930 with 1% KUT PLAST PCE600 / or/ 0.5% ViscoCrete-5930 with 1.5% KUT PLAST PCE600.

Compressive strength

Table 5 exhibits the results obtained from the strength-test for reactive powder concrete at age 3, 7, and 28 days. The results in this table show that the effect of dosage 2% superplasticizer for both types (ViscoCrete-5930 or KUT PLAST PCE600) on the compressive strength of the concrete samples at age 3 days was equal approximately while this effect is different at age 7 or 28 days. But it was noticed that the use of 2% ViscoCrete-5930 led to increasing the strength more than that of using 2% KUT PLAST PCE600 at age 7 and 28 days. It was also noticed that the combined use for both types of superplasticizer with dosages 1.5% ViscoCrete-5930 with 0.5% KUT PLAST PCE600 leads to reach the strength to the maximum value in comparison of the individual use of superplasticizer (ViscoCrete-5930 or KUT PLAST PCE600) or the combined use of superplasticizers with other different dosages, as shown Table 5.

Table 5: The results obtained from the experimental work

Compressive strength(MPa) |

Density (Kg/m3) |

Fluidity (%) |

Mix Number |

||

28 days |

7 days |

3 days |

28 days |

||

57.46 |

43.095 |

33.885 |

2481 |

160 |

1 |

50.891 |

38.168 |

33.604 |

2450 |

155 |

2 |

53.708 |

40.281 |

30.276 |

2475 |

130 |

3 |

60.489 |

45.367 |

23.210 |

2492 |

160 |

4 |

37.341 |

29.126 |

24.946 |

2400 |

130 |

5 |

Saturated Surface Dry Density

Table 5 lists the results obtained from the density test for reactive powder concrete prepared in this study after cured it for 28 days. The results indicate that the concrete samples used 2% ViscoCrete-5930 give a more saturated dry density value than that used 2% KUT PLAST PCE600. It was also observed that the use of both two types of superplasticizer (0.5% ViscoCrete-5930 +1.5% KUT PLAST PCE600) at the same time leads to a decrease in the saturated surface dry density of concrete confirmed with its compressive strength at age 28 days. While the use of 1.5% ViscoCrete-5930 + 0.5% KUT PLAST PCE600 leads to an increase in the saturated surface dry density of concrete obviously confirmed with the compressive strength at the same age. The relationship between the density and the strength of concrete prepared in this study was demonstrated in (Figure 2).

Conclusions

- The use of 2% ViscoCrete-5930 in the preparation of concrete increases its workability, compressive strength, and density more than that of 2% KUT PLAST PCE600.

- The use of 1.5% ViscoCrete-5930 with 0.5% KUT PLAST PCE600 in the preparation of concrete better than the use 2%ViscoCrete-5930 or 2%KUT PLAST PCE600 individually.

- The increasing dosage used of KUT PLAST PCE600 used with ViscoCrete-5930 in the preparation of concrete leads to decrease workability, compressive strength, and density in contrast that at the increasing dosage of ViscoCrete-5930 in the hybridization case it with KUT PLAST PCE600.

References

- Alsadey, Salahaldein.Effect of Superplasticizer on Fresh and Hardened Properties of Concrete. 2015;1(2):70–74.

- Neville AM. Properties of concrete, Pearson. Prentice Hall. 2005; 255- 262.

- Ramachandran VS, Beaudoin JJand Shihua.Concrete science. Heyden & Son Ltd. 1981;9:130- 138.

- Yamakawa C, Kishitani K, Fukushi Iand Kuroha K. Slump control and properties of concrete with a new superplasticizer. II: High strength in- situ concrete ork at Hikariga- oka Housing Project, Chapman and Hall. 1990:94-105.

- Borsai A.Effect of superplasticizer type on the performance of high- volume fly ash concrete. 1994.

- Iraqi Standard Specifications, “Characteristics of OPC” Central Agency for Standardization and Quality Control, no.5, 1984.

- ASTM C778. Standard Specification for Standard Sand. Annual book of ASTM Standards. 2013.

- ASTM C 1437. Standard Test Method for Flow of Hydraulic Cement Mortar. Annual book of ASTM Standards. 2013.

- ASTM C 109. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). Annual book of ASTM Standards. 2013.